V track can be fabricated out of angle iron and flat bar if you like doing your own welding or you can buy prefabricated sections to install using concrete anchors.

Inverted angle iron track.

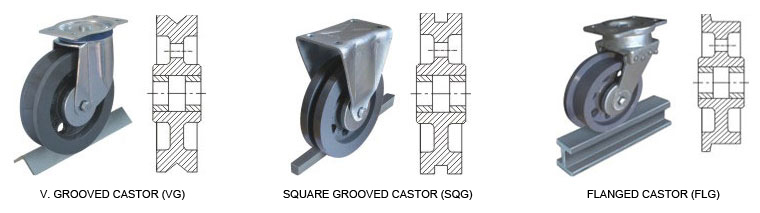

V groove wheels or casters are named for the v shaped groove that allows for riding along an inverted angle rail or track.

Frequently used in tandem with flat faced wheels the v grooved wheels provide capacities of up to 8 tons and are comprised of either cast iron forged steel stainless steel or even phenolic plastic.

V groove caster wheels are designed to guide equipment by rolling on inverted angle iron track.

A relief groove in the v assures proper weight distribution and makes wheel and track self cleaning while a partial flat tread permits rolling the wheels directly on floors as well.

In principle v groove wheels are designed to guide equipment by rolling on inverted angle iron tracks or round iron bars.

V groove caster wheels are designed to guide equipment by rolling on inverted angle iron track.

Most v groove wheels also have sufficient flat surfacing on the sides of the groove to allow for rolling on floors when off the track.

Hard rubber and sometimes plastic.

Forged steel v groove caster wheels minimize wear of the v groove sides and are best for frequent operation.

Essentially if groove wheels are used on a flat surface then it becomes a regular wheel caster.

Cast iron and steel v groove wheels are the most.

Wheels are cast with reinforced section at maximum stress points.

Elevated track minimizes problems caused by floor debris.

Running v grooved wheels on inverted angle iron track is a popular and low cost method of taking loads off the floor and creating production line flow.

Elevated track minimizes problems caused by floor debris.

What is the function of the v groove.

V groove surface and face are machine finished.

They are also used with hand or conveyor trucks.

Track sections under 8 long can be shipped ups for a reasonable cost but.

Most companies simply hot dip galvanize the track although liftmaster sells theirs with a black finish.

V groove wheels finished with green alkyd enamel are designed for track or floor operation on inverted angle iron track in production lines and are also used with hand or conveyor trucks.

Elevated track minimizes problems caused by floor debris.

These wheels handle loads from 800 to 6 000 lbs.

V groove wheels are for track or floor operation on inverted angle iron track in production lines.

Inverted angle iron and v grooved wheels combine to create effective in plant production flow.

When not operating on track the considerable wheel tread on each side of the v groove allows for use on.